Rezinfluor FFKM

Rezinfluor FFKM

Rezinfluor FFKM

Rezinfluor® FFKM PERFLUORELASTOMER

REZINFLUOR brand perfluoroelastomers are a class of elastomers corresponding to the code >FFKM< according to the classification given by the international standard ASTM D 1418.

Therefore, the >FFKM< code does not correspond to a single material, but the >FFKM< family constitutes a class of many different formulation types, each of them specific for the various application orientations.

The very high chemical inertia, deriving from the strong presence of fluorine (F), >72%, chemically linked directly to carbon (C) with one of the most stable chemical bonds existing in terms of energy, gives this class of elastomeric materials resistance characteristics chemical and thermal properties superior to those of all other elastomers.

For many areas of use, from process chemistry to oil & gas, via the semiconductor industry or for applications in the aeronautical propulsion sector, there is currently no alternative to the use of perfluoroelastomers, >FFKM<, precisely in due to their performance specificity.

Applications

- Seals and o-rings in pumps, reactors and flange joints

- High performance parts for aerospace, oil and gas, transportation and chemical process equipment

- Semiconductor processing

- Materials in contact with food

Advantages

- Resists over 1,800 different chemicals

- Stability at high temperatures up to 327°C

- Maintains seal integrity

- Reduces maintenance and operating costs

- Meets safety standards for pharmaceutical and food industries

- Available in standard and special compounds formulated for custom use

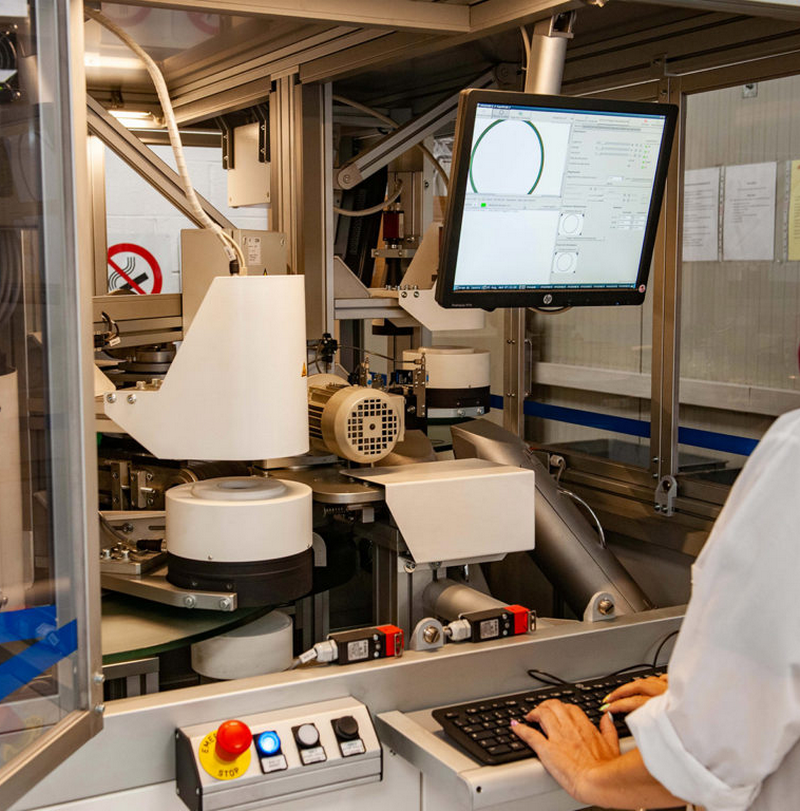

ISO 8 Clean Room

The Rezingom Clean Room is classified according to the degree of cleanliness of the air inside the controlled environment.

The Clean Room class is the level of cleanliness to which the room complies, based on the quantity and size of the particles per cubic meter of air (1-9).

The primary authority in NAFTA is the ISO classification system ISO 14644-1

FFKM Compound Technical features

- Unmatched resistance to the vast majority of chemicals compared to all other elastomers;

- Thermal stability up to ~260°C/275°C and for some grades up to 300°C/325°C/340°C;

- Excellent ability to recover the imposed deformation (Compression Set);

- Very low permeability to fuels and many hydrocarbon gases;

- Excellent performance in lubricating systems with high oxidative stability typical of aeronautical turbines;

- Unmatched resistance to petroleum gases with high concentration of H2S;

- Depending on the formulation resistance to water vapor up to 200°C and even ~300°C;

- Very high fire resistance.

Application fields of specialization

Rezingom was born to face the probative challenge of supplying a complex and highly competitive market such as the automotive one and entering the Vendor List of the major automotive brands such as Mecedes BMW Volkswagen Volvo and Tesla.

The various entry barriers in terms of quality specification and company organization induce Rezingom to continuously improve its performance by acquiring a mentality and a level of expertise capable of dealing naturally and reliably with other production sectors such as Oil & Gas, Food and the medical field

Oil & Gas

Food

Medical & Pharma

Semiconductors

Static Applications in Valves

Dynamic Applications in Mechanical Seals for Pumps

Quality control : Zero defects

“0 COMPROMISES IN QUALITY”

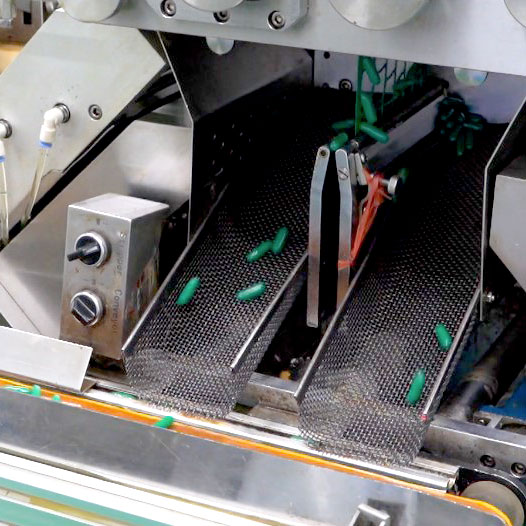

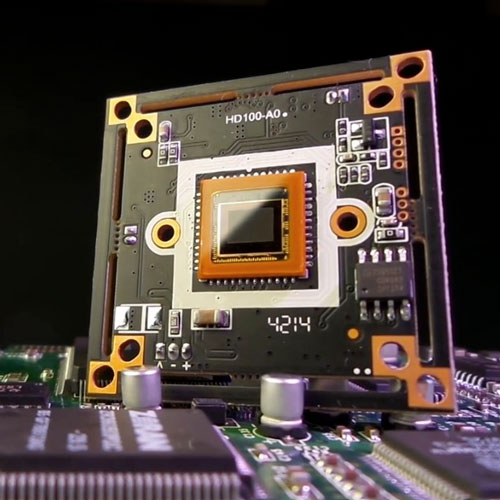

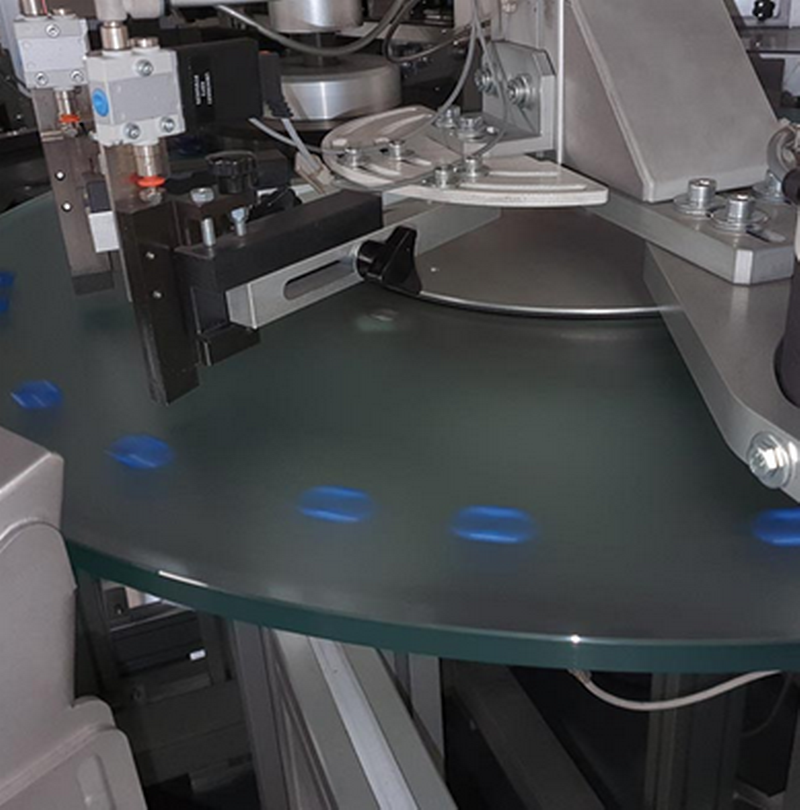

The selection and inspection takes place for all the articles produced using the latest generation UTP VISION automatic machines with control with high-speed cameras and 360° definition with detection of any surface defects and control of dimensional congruity and tolerances as per specification of the customer.

Get to know our Rezinfluor product range®

For more details and specifications on Rezinfluor products, download the PDF by clicking on the button below.