Company

Company

Company

Corporate History

The location in the most important historic gasket production district in the world allows it to efficiently optimize the value chain thanks to the large number of associated companies which logistically allow it to combine the very high quality of its outputs with a service suitable for new market needs.

The profound know-how in the automotive environment of the founder Ing. Alberto Arcangeli, allows Rezingom to immediately and successfully deal with the narrow qualitative entry barriers of the biggest brands in the automotive industry such as Volkswagen Volvo Mercedes and BMW, becoming their "official supplier ", passing the required audits.

Since 2022, strong investments have been directed towards the production of gaskets in Perfluorelastomer (FFKM) with the creation of an ISO8 clean room and the purchase of two further presses dedicated to the production of "REZINFLUOR" registered trademark which defines the range of products for the use in application fields such as Petrochemical, Pharmaceutical and Food.

Why Rezingom

Technical consultancy

Thanks to the experience accumulated so far in product development and in the industrial batch production of rubber seals, Rezingom gladly cooperates with the customer by making its knowledge of the elastomer product available to him if it is required for the development of the project. In this way, together with the customer, it is possible to define the best geometry of the piece which allows its production optimized to the concept of "zero defects" strategy.

Experience and Know-how

Rezingom is able to satisfy its customer's requests when the need arises to develop suitable materials, which comply with the requirements established by our customers and are also compliant with other specific standards, even the most stringent such as for example those of the automotive sector. Our experience with materials, FFKM FEPM FKM NBR, EPDM, ACM, HNBR, AEM, FPM, allows us to successfully address the technical specifications of over 1800 application fields.

Technology

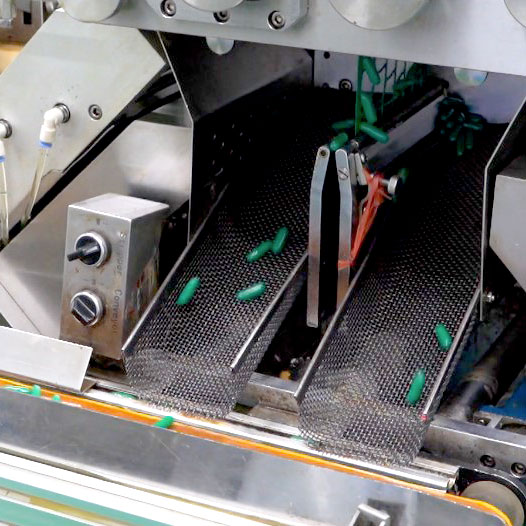

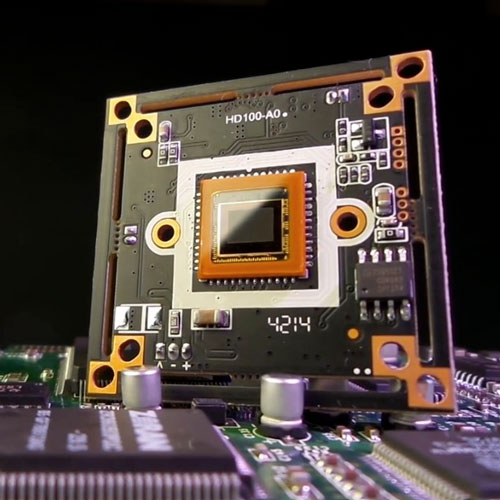

Rezingom oversees its activities with a high technological level having a fleet of modern injection and compression machines for production and sophisticated tools for quality control of products during the production process. 100% final inspection of the batches produced on an automatic machine with video camera for a guarantee of the piece according to specification and of excellent quality.

Application fields of specialization

Rezingom was born to face the probative challenge of supplying a complex and highly competitive market such as the automotive one and entering the Vendor List of the major automotive brands such as Mecedes BMW Volkswagen Volvo and Tesla.

The various entry barriers in terms of quality specification and company organization induce Rezingom to continuously improve its performance by acquiring a mentality and a level of expertise capable of dealing naturally and reliably with other production sectors such as Oil & Gas, Food and the medical field.

Automotive

Oil & Gas

Food

Medical & Pharma

Semiconductors

Static Applications in Valves

Dynamic Applications in Mechanical Seals for Pumps

Our history

- 2007 Birth of the company Rezingom S.r.l.

- 2008 ISO 9001 certification obtained with TAW-Cert.

- 2010 First process audit by the automotive sector customer

- 2010 Move to the new headquarters in via Molinaretti, 28

- 2014 New ISO 9001 certification obtained by Quality

Austria - 2017 16.05.2017, ISO/TS 16949 certification

- 2018 30.06.2018 IATF 16949 certification

- 2022 Installation of Clean Room Iso 8

- 2023 New "High performance Products" production complex in Telgate

Mission / Vision

Promote the dissemination of know-how through the training and updating of the Rezingom team in order to make the staff aware of the correct interpretation of the customer's needs and the importance of promoting a positive and preparatory "customer experience" for maximum customer satisfaction.

Resources efficiency

At Rezingom, we encourage energy saving and combat any waste at all company levels, promoting the conscious use of resources by triggering a virtuous process of energy efficiency and productivity.

Education, training, internships and degree thesis in Rezingom

Rezingom attaches great importance to the level of education and training at any hierarchical level of the team to facilitate the transfer of experience and professionalism between collaborators with greater specific preparation and less experienced ones.

Rezingom is sensitive and available with its structures and technologies towards young people who are at the end of their studies and need to spend a period of time in a company that offers them the opportunity to get to know the world up close of work by offering opportunities