Quality Control

Quality Management System

The Quality Management System developed in Rezingom has among its tasks that of spreading the "zero-defect" strategy at all levels of the company and overseeing its correct application. The excellent quality of the products made by Rezingom is a central element for the Company's competitive strategy and contributes to customer satisfaction. In order to be able to supply our customers with a very high quality product, the process and the piece produced are controlled, validated and recorded in all the operations carried out along the value chain, from the entry of the raw material into the factory up to the approval for the shipment of the pieces to the customer.

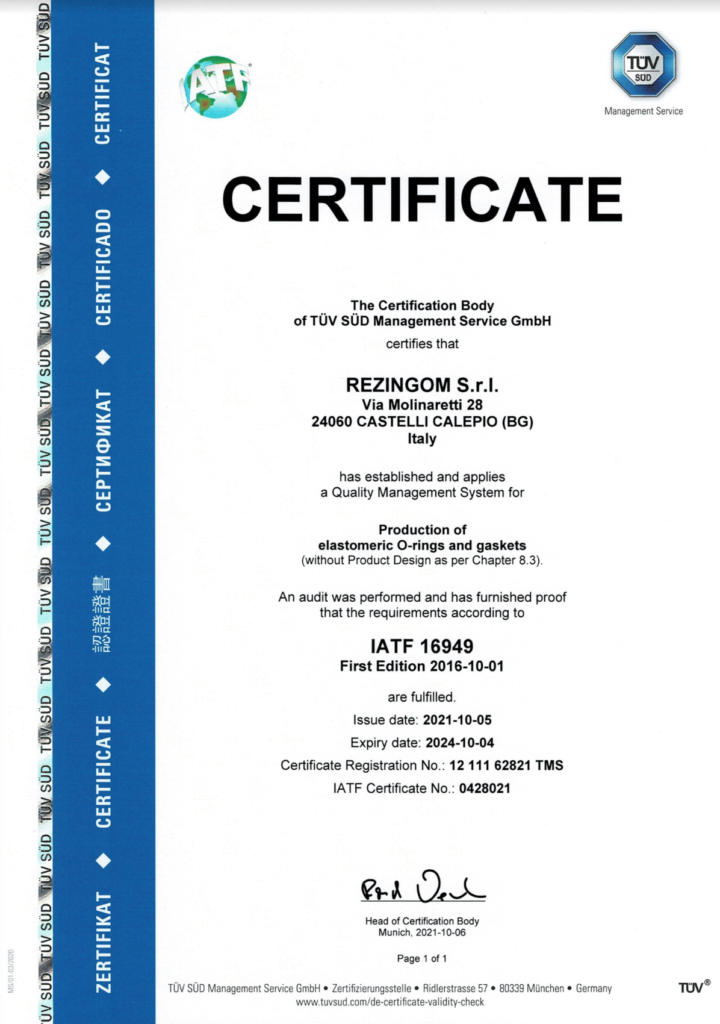

Certifications

A fundamental contribution to successfully managing the growing demands for product and service quality that the market requires of us is ensured by our Corporate Management System, certified according to DIN EN ISO 9001:2015. Rezingom has been certified according to ISO 9001 since its foundation in 2008. For our “automotive” business unit, Rezingom applies the recommendations contained in ISO/TS 16949 and the subsequent adaptation IATF 16949. Rezingom's management system is oriented to the process: Every process that takes place in the company, such as production processes, organizational and decision-making processes, or documentation management, are modeled in compliance with IATF 16949, and in particular with the implementation of the principle of "continuous improvement process ”. The Rezingom Management System has been certified according to IATF 16949 since 07.30.2018.

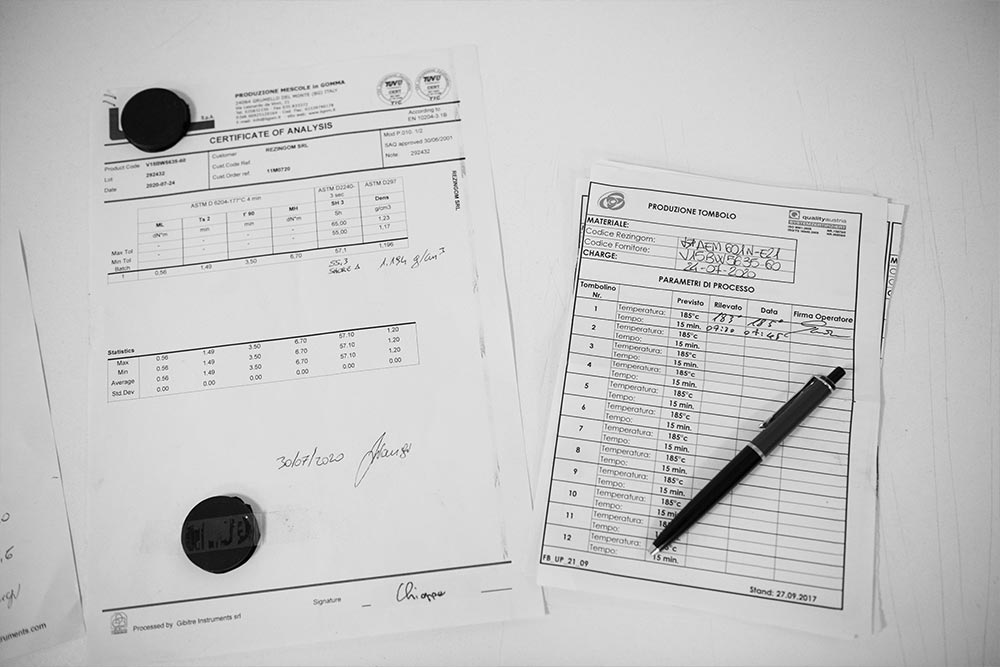

Compound check in

In Rezingom, the approval of the incoming raw materials is performed by the laboratory technician, who, by taking samples, carries out one or more "conformity tests", verifying the conformity of the physical-mechanical characteristics of the compound.

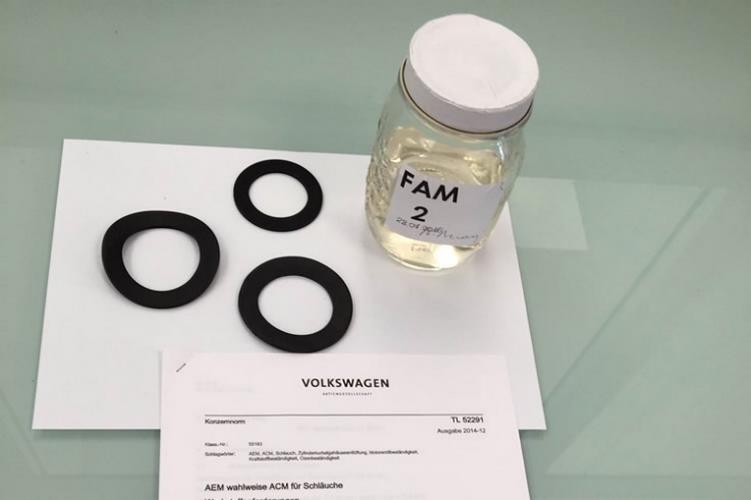

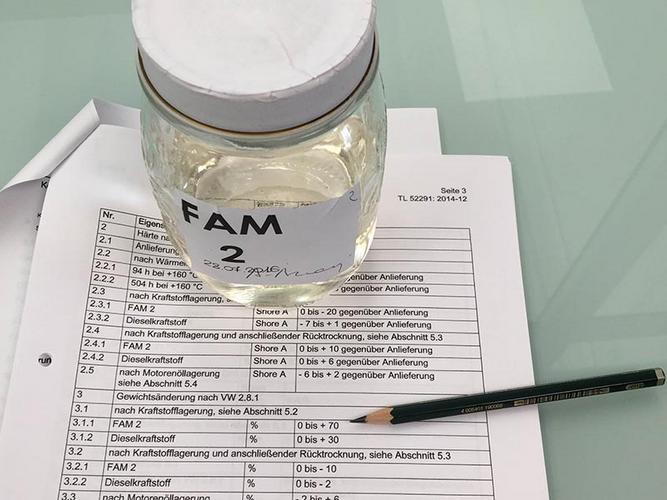

Among the special blends made up of fine basic polymers, such as AEM, HNBR, EPDM, FKM, NBR, MVQ and others, which have been developed in the chemical laboratories of our suppliers on Rezingom specification and in compliance with the demanding requirements, among others, of the automotive industry, such as the specifications DBL 6015, DBL 6038, BMW GS 93010, VW TL 52316, VW 2.8.1 etc.

These are then used in the production machine with the reference mould, in operating conditions, to verify its behavior and then request optimization from the supplier if necessary.

Further tests on the material are possible with the use of more complex analysis tools and therefore can only be performed in the laboratories of our compounders according to Rezingom specifications:

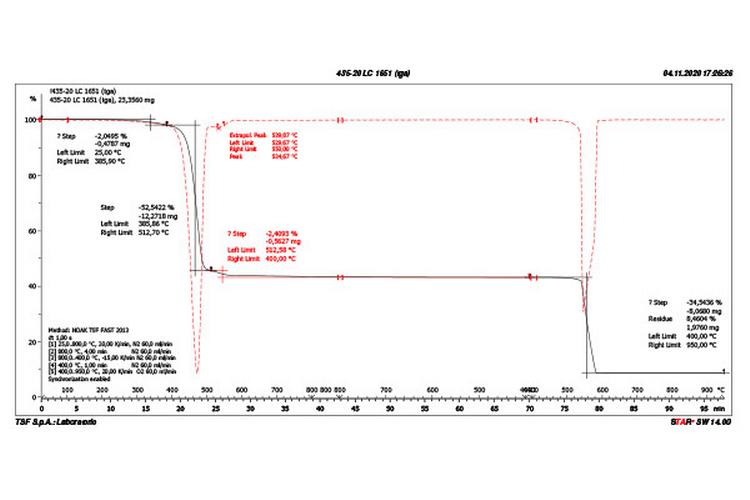

- TGA analysis

- Infrared spectroscopy (IR) and CT thermal analysis

- DSC, TMA and Tg (glass transition temperature) analysis

- DMA analysis

- Aging in air or other agents

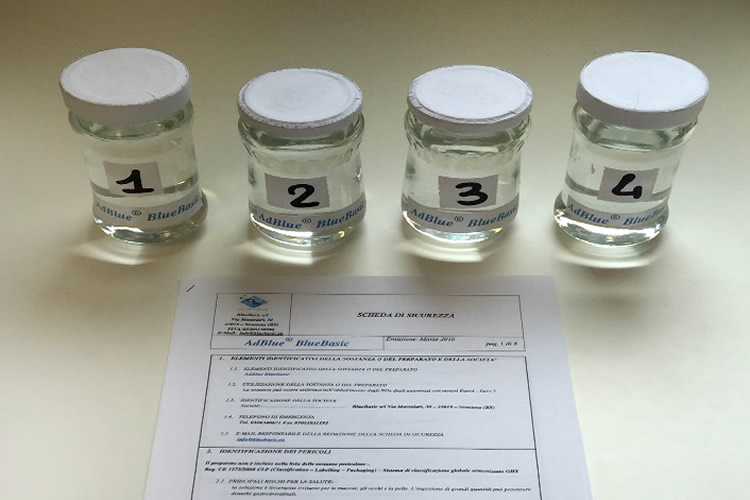

In the photo, some of the analyzes that are performed in Rezingom: Aging in AdBlue and FAM 2.

Production intermediate check

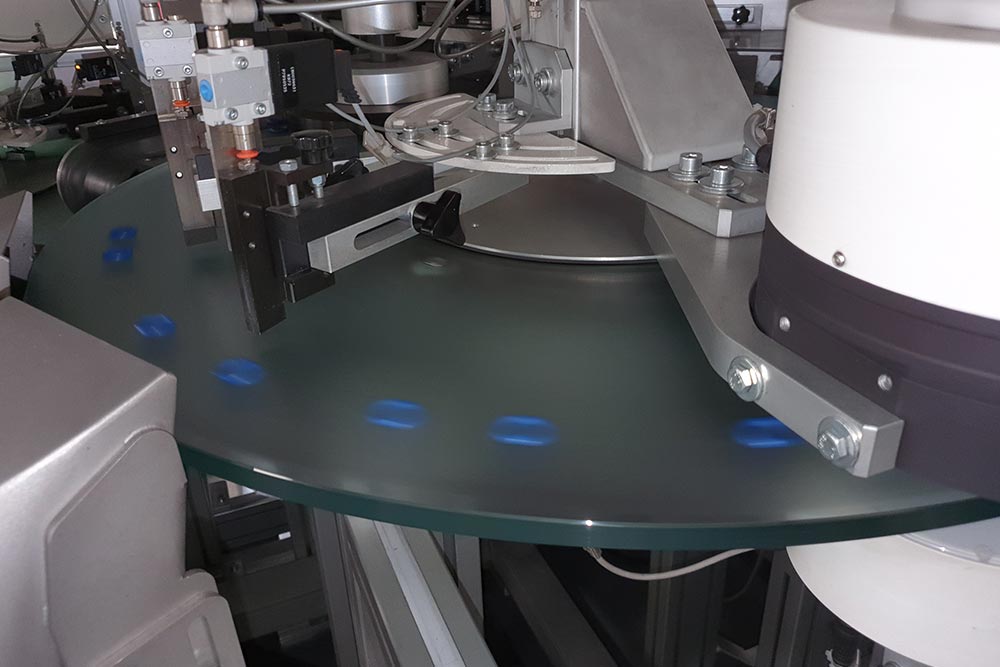

The verification of compliance with the specifications of our products is carried out through the double check of the process parameters and of the piece itself along the entire value chain, contributing to the reduction of rejects and waste and contributing to the increase in the quality level of the products.

Temperature verification control on mold cavities during production.

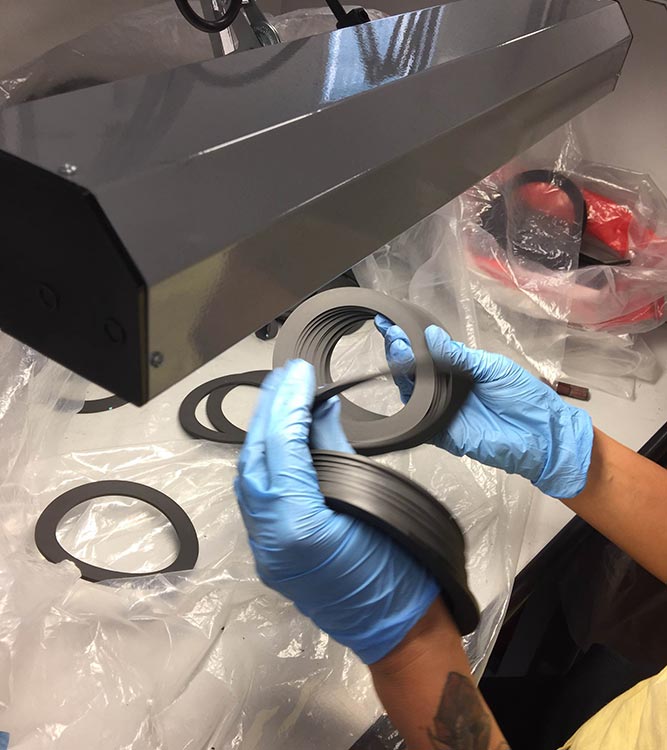

Last check prior the shipment

Every single product made in Rezingom is checked individually at the end of the value chain to verify that they comply with the specifications and requirements defined by the customer.